Name:YG026E-1000 Electronic Multifunctional Fabric Strength Tester

Scope of application

Used for stretching, tearing, bursting, constant elongation, constant load, elasticity, suture slip, etc. of various textiles Mechanical performance test such as peeling.

Applicable Standards

FZ/T98008-2011 “Electronic Fabric Tensile Strength Tester”

GB/T3923.1 Fabric Strip Sample Tensile Test (ISO 13934.1)

GB/T3923.2 Fabric Grab Sample Tensile Test (ISO 13934.2)

GB/T3917.2 Tear Resistance of Textile Pants (Single Seam) (ISO 13937.2)

GB/T3917.3 Tear Resistance of Textile Trapezoidal Samples (ISO 9073.4)

GB/T13772.1 Resistance to Slip at Seam Threads of Woven Fabrics Using the Constant Slip Method (ISO 13936.1)

GB/T13772.2 Resistance to slippage at seam yarns of woven fabrics by constant load method (ISO13936.2)

GB/T13773.1 Seam strength by strip method (ISO13935.1)

GB/T13773.2 Seam strength by grip method (ISO13935.2)

GB/T19976 Top Burst Strength by Steel Ball Method

FZ/T80007.1 Peel Strength Test of Adhesive Lining in Garments

FZ/T20019 Degree of Seam Separation in Woolen Woven Fabrics

FZ/T70006 Elastic Recovery Rate Test of Knitted Fabrics

GB8688 Degree of Seam Separation Test

FZ/T70007 Underarm Seam Strength

ASTMD5034 Fabric Grip Method Tensile Test

ASTMD5035 Fabric Strip Method Tensile Test

ASTMD2261 Fabric Single Tongue Tear Strength Test

ASTMD5587 Fabric Trapezoidal Tear Strength Test

ASTMD4964 Elasticity Test

ASTM D3936 Peel Strength Test

ASTM D1683 Seam Slip Resistance Test

JIS L1096 Fabric Tensile and Tear Strength Test

GB/T 23318, GB/T 24442.1, FZ/T 01030, FZ/T 01031, FZ/T 01034, FZ/T01085, FZ/T20019, FZ/T60005, FZ/T60006, FZ/T81007, ISO3303, ISO13936.1, ISO13936.2, ISO13936.3, ASTM D2724, ASTM D5733, etc.

(The above list includes some representative standards, and some functions require specific clamps and sensors selected based on actual conditions for implementation.)

Instrument characteristics

1. Utilizes precision ball screws and AC servo drives to achieve fully digital speed closed-loop control, offering advantages such as stable speed, wide speed range, and high positioning accuracy. The gauge length and tensile speed can be freely set digitally.

2. Touchscreen computer control provides detailed real-time and historical data, reports, and various graphics, and establishes a database.

3. Optional grippers are available, including pneumatic grippers.

Technical Parameters

1.Test method:

According to the internationally preferred principle of constant velocity elongation (CRE)

2. Force measuring system:

high-precision force sensor

3. Measuring force range:

1%~100% of full scale, 500N/1000N/2500N/5000N/10000N

4. Clamping method:

manual clamping, pneumatic clamping

5. Minimum graduation value: 0.1N

6. Force measuring accuracy: ≤±0.2%F•S

7. Clamping distance:

automatic positioning, digital setting

8. Accuracy of clamping distance adjustment: ±0.1mm

9. Speed control system:

AC servo speed control system

10. Stretching speed: 0.01-1000mm/min digital speed regulation, error ≤±2

11. The maximum stroke of the instrument:

600mm (beam) (otherwise customizable)

12. Gantry width: 500mm

13. Elongation resolution: 0.00lmm

14. Sampling frequency: 2000 times/sec

15. Power supply: AC22OV±10% 50Hz 1KW

16. Dimensions: 720×500×1690mm (L×W×H)

17. Weight: 200kg (standard)

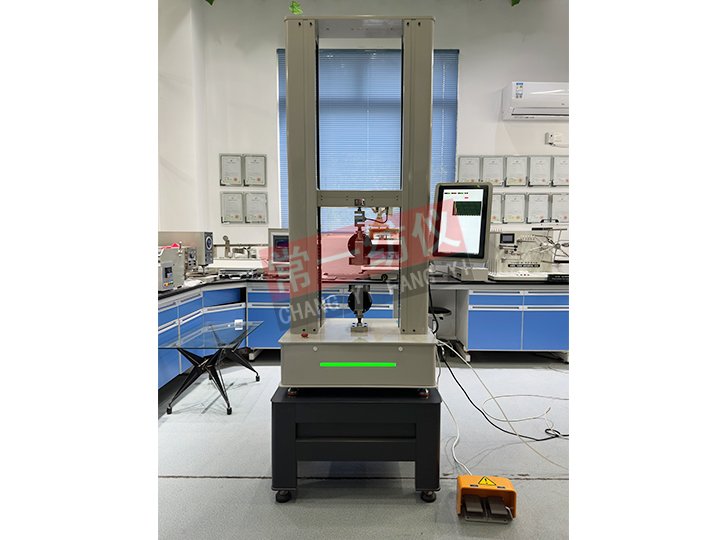

Instrument appearance pictures

Desktop dual-column mainframe with a large-screen Chinese LCD display, featuring data storage, retrieval, statistics, and printing functions. It can be independently configured with a 24-pin dot matrix printer to print test data reports.

It can also be configured with a computer, color monitor, and inkjet printer to output graphs and reports.

It achieves bidirectional interactive control between the mainframe panel button operation (microcontroller) and computer keyboard operation, allowing users to choose either option as needed.

The computer runs on the Windows operating system. The operating interface offers a choice of Chinese or English text.