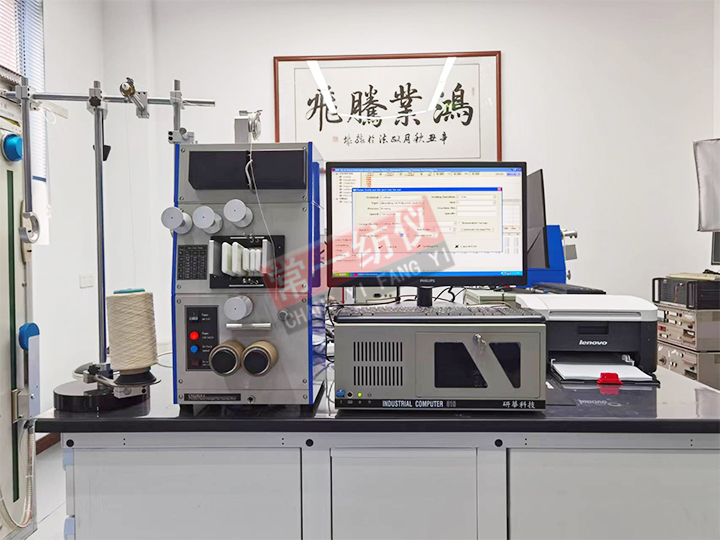

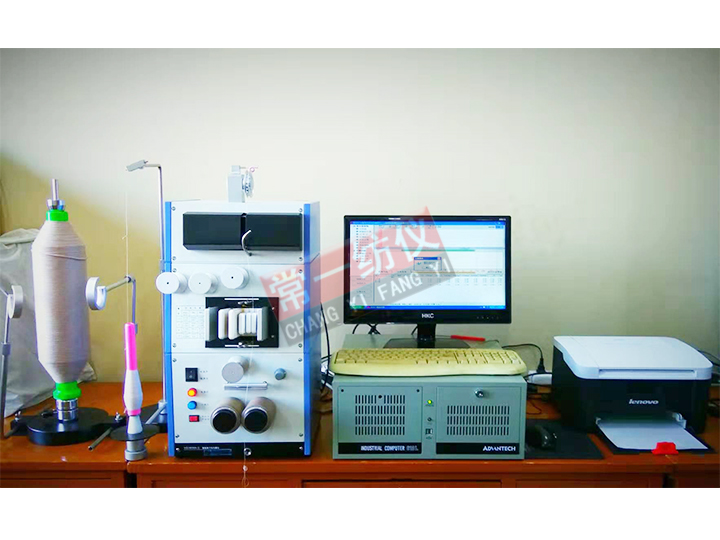

Name:YG191XH Intelligent Strip Drying Hairiness Meter

一、Scope of application of strip dryer

1.YG191XH Intelligent Strip Drying Uniformity Meter (hereinafter referred to as Strip Drying Meter) adopts the latest achievements of advanced data processing technology and computer software technology, with high testing precision. Good stability and consistency, strong anti-interference ability, it can be customized according to the different models of each factory “expert software”, saving staffing, improve efficiency, is the cotton textile mills, woolen textile mills, the quality of the necessary precision testing instruments.

2. Strip dry meter adopts reliable industrial computer with strong adaptability, realizing automatic zeroing and automatic leveling; the monitoring software is based on the most popular WINDOUS operating system, making full use of graphic processing technology, with user-friendly interface, easy operation, flexible printing, and then can be printed after the test. The advanced file system provides users with data storage and maintenance information, which plays a leading role in controlling and improving yarn quality for users.

二、Technical Parameters of Strip Dryer

1、Sample data acquisition:

(1) Five substrate capacitive detection slots: 4 (1 slot for strips, 1 slot for roving, 2 slots for spinning)

(2) Measurement of yarn number dry range: 4.0tex -20Ktex

(3) Measurement of yarn hairiness range: 4.0tex-160 tex

(4) Dryness test speed: 4m/min, 8m/min, 25m/min, 50m/min, 100m/min, 200m/min, 400m/min;

(5) Feather test speed: 50m/min, 100m/min, 200m/min, 400m/min;

(6) Strip dry test time: 0.5min, 1min, 2min, 2.5min, 5min, 7.5min, 10min, 20min, 30min;

(7) Feather test time: 0.5min, 1min, 2min, 2.5min, 5min, 7.5min, 10min, 20min, 30min;

2, coefficient of variation CV% variation length curve: CV% test range: 0.20%-99.99

3, Variation - length curve: cutting length 1CM ~ 990M

4、Drift rate DR test range: 0.01%~99.99

5、Relative branch RC value: the difference between the average value and the specimen

6、Strip dry, hair plume spectrogram

(1) Measurable wavelength range: 0.1CM-6000M; number of standard spectrogram channels: 85;

(2) Fine-type measurable wavelength range: 1CM ~ 2980M; the number of spectrogram channels: 170

(3) The surface can display 1~500 spectrograms, while displaying the CV value of the trunk, commonly used two-block sensitivity threshold: -40%, +35%, +140%; -50%, +50%, +200%; you can also hide the spectrograms, and directly display the CV% value of the experiment; the hairiness index H value, the standard deviation of the hairiness index SH value.

7、Strip dry line density frequency distribution graph:

(1) It can draw the frequency distribution chart of line density within the range of -100%~+100% and beyond -100%~+100%;

(2) According to the production requirements to print a frame of 400M ~ 0.01M line density frequency distribution map

(3) According to the value of the defects will be line density frequency distribution graph stretched, pulled thin to distinguish the process, or operation, mechanical reasons.

8、Hair plume line density frequency distribution chart:

Spinning different raw materials, line density frequency distribution chart is different.

9、Strip dry, hairiness spectrogram curve section automatically switch to view, analyze the cause of yarn defects.

10、Fault value

Details: -30% , -40% , -50% , -60%;

Coarse knots: +35% , +50% , +70% , +100%;

Cotton knots: +140% , +200% , +280% , +400%;

11、Statistics function

(1) Test data statistics: average mean/km, ****** value max, minimum value min;

(2) Each test data: optional. Years, months, days on the test results by species statistics

(3) can automatically draw a variety of sub-numbers, sub-numbers, sub-strips, roving, spinning and rotor spinning yarn dry, quality control charts, statistical analysis against the bulletin.

12、Able to automatically draw the hairiness and quality control charts of sub-species, spinning number and rotor spinning spinning yarn, and analyze them statistically according to the bulletin.

13、expert analysis software:

(1) detection, can automatically switch to the expert analysis software and database connection, storage, maintenance information.

(2) Customized expert analysis software: “Capacitive strip dryer spectral analysis manual” 900,000 words, the author of the book, senior engineer Xiao Guolan personally visit, combined with the production of practical issues taught.

14、the working environment: temperature 20 ± 10 ℃, relative humidity 65 ± 5%;

15、Power supply: single-phase AC 220V±10%, 50Hz

三、Instrument shape picture